Description

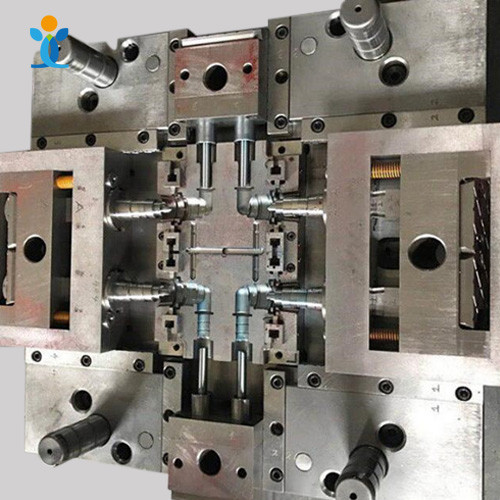

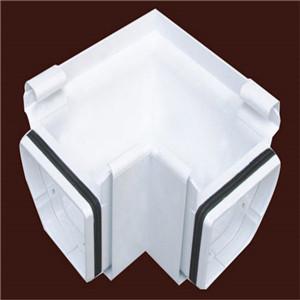

Professional OEM plastic mould / molding service maker plastic injection mold

Product Description

Basic information:

|

Mold Base |

LKM, HASCO, DME or your requirement |

|

Mold Material |

45#, P20, H13, 718, 1.2344, 1.2738 and so on |

|

Standard |

HASCO, DME and so on |

|

Product Material |

PC/ABS, ABS, PC, PVC, PA66, POM or other you want |

|

Runner |

Cold/Hot Runner |

|

Gate Type |

Side gate, Sub gate, Pin point gate, Edge gate etc |

|

Mould Weight |

50kg-10Ton |

|

Injection Machine Type |

80-2000Ton |

|

Standard for Product Appearance for graining |

MT(Mold Tech), YS |

|

The Way of Color Contrast for Plastic |

RAL PANTONE |

|

Certificated |

ISO 9001:2015 Certificated, SGS Certificated |

Yixing technology uses the lasted new version software design programs: CAD, SolidWorks,. you can send any type of drawings dxf,pdf,step,or iges. We also give you service is reverse engineering, we can follow your sample to create a completely new 3d drawings and the molds. Because of the patent problems, we also give you value-added engineering service. Products and molds will always be designed to the specifications of the customer needs.

SPI Mold Finish Standards

The Society of the Plastics Industry, or SPI, establishes standards for the United States plastics industry. Among the SPI standards is one defining the degree of polish on the inner surfaces of the molds used to form plastic products. The SPI standards specify 12 grades of mold finish ranging from mirror-perfect to dull. Various companies offer illustrative sample kits consisting of steel discs or strips polished to the different SPI grades.

Shiny Finishes

SPI grades A-1, A-2 and A-3 specify high gloss finishes on hardened tool steel molds buffed to a mirror sheen with fine diamond powder suspended in oil. Plastic parts made to these grades show no mold parting marks or tool or machining marks. An A-1 mold finish has no more than 1 millionth of an inch deviation from perfect. An A-2 finish allows up to 2 millionths of an inch deviation, while an A-3 finish allows deviation of up to 3 millionths of an inch from perfect. These super smooth and shiny finishes are very expensive and time-consuming to achieve. They are specified to make plastic mirrors, visors and other optical plastic goods.

Semi-Gloss Finishes

SPI grades B-1, B-2 and B-3 specify semi-gloss finishes with some sheen, on hardened tool steel molds polished with ultra-fine-grit sandpaper or emery cloth. Again, plastic parts from these molds can't show mold, tool or machining marks. Grade B-1 allows a 3 millionths of an inch deviation from perfect. Grade B-2 allows up to 5 millionths of an inch deviation, while Grade B-3 allows up to 10 millionths of an inch deviation from perfect.

Matte to Dull

The SPI's grades C-1, C-2 and C-3 specify matte finishes from steel molds polished with fine stone powder. These finishes can't show mold, tool or machining marks. Grade C-1 allows up to 12 millionths of an inch deviation from perfect, Grade C-2 allows up to 28 millionths of an inch deviation and Grade C-3 allows up to 42 millionths of an inch deviation. SPI grades D-1, D-2, D-3 specify dull, nonreflective finishes from steel molds sandblasted with glass beads or iron oxide powder. These blasted finishes are used on diecast or thermoset plastic industrial parts. Grade D-1 allows a deviation of up to 12 millionths of an inch from perfect, D-2 allows a deviation of up to 32 millionths of an inch, while Grade D-3 permits up to a 230 millionths of an inch deviation from perfect.

Contact Yixing plastic for more information about getting a quote, placing an order, or for finding solutions to your application.