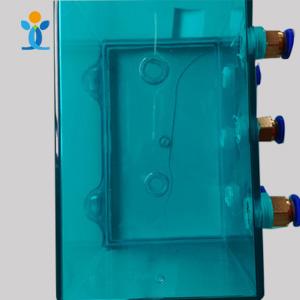

Iso certificated supplier of custom injection molding parts

Over 20 years experience and developed1500+ injection molding parts

Since our founding in 2010, Yixing has been devoted to developing the highest-quality injection molding parts. Yixing plastic specializes in low-to-high-volume plastic injection molding for a wide range of industries including industrial, medical, marine, aerospace, & consumer products.

Production capability for injection molding

Our injection molding machines range from 50 tons to 1600 tons of clamping force, which ensures we can make the parts from 1g to 20000 g.

We work with thermoplastics and thermosets, offering ISO 2768 or tighter tolerances, can make 0.005 inches high precision injection molding parts.

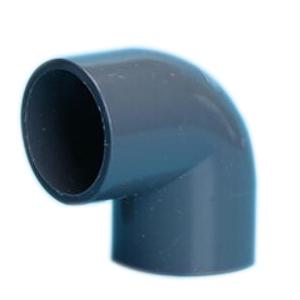

Wide range of injection molding material

You have a wide variety of materials to choose from for custom injection molding service. The following materials we can use for injection molding:

- LDPE

- PP

- PA

- PE

- TPE

- TPU

- PLA

- ABS

- ASA

- HDPE

- EVA

- PS

- POM

Where Is Injection Molding Commonly Used?

Plastic injection molding has come a long way since its inception in 1872. In current manufacturing, injection molding has become an important manufacturing process across numerous industries:

-

Automotive Plastic parts: Produces various components, from interior

trim to under-hood parts

-

Consumer Electronics Plastic parts: Creates device housings and

intricate internal components

-

Medical Plastic parts: Fabricates precise instruments, syringes, and

even implantable devices

-

Plastic Toys: Shapes durable, colorful playthings for children of all

ages.

-

Plastic Packaging: Forms containers and lids for a wide range of

products

Tooling & Parts Costs for injection molding

Target Cost Planning for Custom Injection Molding. The cost of custom plastic injection molding projects for long-term production varies greatly. Simple injection molding tooling may range anywhere from $1000 to $10,000. More complex, multi-cavity or high-production injection molds cost significantly more. Calculating the total cost for injection mold and injection molding part prices involves assessing many factors, such as:

1. Injection Molding Parts Complexity2. Injection Mold Construction

3. Number of Mold Cavities

4. Injection Molding Part Size

5. Injection Mold life

6. Injection Molding Part surface requirements

7. Other requirements.

Why choose Yixing Plastic for your injection molding needs?

1. Ideal for injection mold design and analysis.2. Maintenance-free, longer service life.

3. 20 years injection molding experience, More than 1500 new molds and parts be produced.

4. ISO9001 certificated company, Strict quality control system, provide ROHS/CE certification.

5. Standard control Process.We make the DFM based on custom requirements, after custom conforms it, we start to make the mold. And after making the sample, we send it to the client to confirm the first time, if it is ok, we start to do mass production.