Description

|

Product Name |

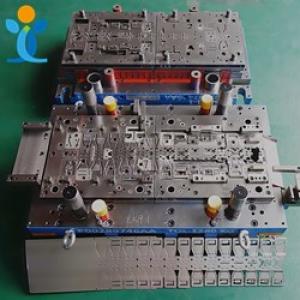

China quality customized overmold plastic injection insert molding |

|

Quality Assurance |

ISO 9001 |

|

Mold Base |

HASCO, LKM, DME Standard |

|

Mold Material |

H13, 2344, 718H, NAK80, P20, S136 |

|

Runner System |

Cold runner / Hot runner (Mold Master, INCOE, YUDO, HASCO, Synventive) |

|

Mold Life Time |

100,000 ~ 1,000,000 shots |

|

Product Material |

PA, PA6/6+GF, ABS, POM, PC, PP, PET, TPE, PVC, HDPE, PPS |

|

Export Country |

Germany, Poland, Czech, Finland, United State, Mexico, Thailand, Singapore |

|

Lead Time |

4 ~ 8 weeks |

Plastic injection insert molding is an effective alternative to assemblies manufactured using soldering, adhesives or fasteners, with benefits including:

· Reduced assembly and labor costs (Molded as one assembly)

· Reduced size and weight (Insert molding allows for reduction of part size and weight because parts are joined with strong, light-weight plastic resin and fasteners or connectors are eliminated)

· Improved component reliability (Insert molding of components ensures proper alignment, prevents loosening and the plastic resin can provide improved resistance to vibration and shock)

· Improved part strength and structure (Insert molding combines the physical strength of the plastic resin and insert to produce one seamless plastic part)

· Enhanced design flexibility (Custom plastic insert molding allows for almost unlimited configurations and material combinations)

· Consolidation of components (Insert molded components enable part and inventory cost reductions)

Yixing plastic can help you for all your plastic enclosure project from concept design, prototype, small order testing and mass production.

Contact us for more information about getting a quote, placing an order, or for finding solutions to your application.