Description

Yixing Plastic uses the lasted new version of software design programs: CAD, and SolidWorks. You can send any type of drawing dxf, pdf, step, or iges. We also give you the service is reverse engineering, we can follow your sample to create completely new 3d drawings and molds. Because of the patent problems, we also give you value-added engineering services. Products and molds will always be designed to the specifications of the customer's needs.

Mold Design For Manufacturing (DFM) Report

Design For Manufacturing (DFM) report, it's a bridge between product developer and mold manufacturer. It has been implemented in many manufacturing industries and proved to be a sufficient way to improve efficiency. As a mold maker, the more potential problems you foresee, the fewer risks you had in the manufacturing process. Before we make the mold for you, we need more communication according to the DFM report.

Here is a summary of it.

Resin to be used

Many kinds of raw materials are frequently used, such as PC, PC+ABS, ABS, PS, HIPS, Nylon, and Material with glass or fiber-filled suitability and price different of them are different. More importantly, the shrinkage rate is different, which is a key factor in measurement and tolerance precision.

Draft on all surface

A draft angle is necessary for part release from the mold cavity, but it will change the appearance of the original product design slightly. It should be run through by both the mold manufacturer and designer.

Thickness design

Rib thickness should be around 60% of wall thickness, avoid uneven wall thickness, and avoid thin wall area as much as possible.

Gating way

Gate location selection sometime is critical when the part has a high requirement on surface finish. What kind of gate determines the way to produce and even the mass production cost?

Mechanical structure/Parting line

It's necessary to give a brief introduction of the mold design mechanical structure employed, such as sliders, lifters, etc. Make sure the parting line is accepted.

Finish and engraving

Define the finish of the part surface, it could have many kinds of finish on one part. Define where would be the engraving and contents.

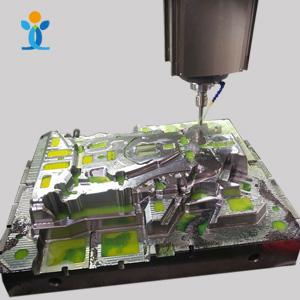

Mold design

Mold design is an important part of the development process when considering the production of a new product. We will make the design based on the DFM report.

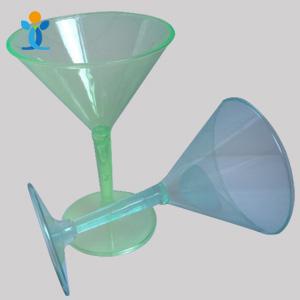

Mold Testing or Sampling

Is sampling for mold needed? In most cases, sampling is necessary. We need to check the surface, the dimension, and the function test.

Mass production

After confirming the sample, we will start mass production.

Yixing Plastic factory also has additional capabilities including bonding, painting, printing, and basic assembly of electronic components and plastic products. Any customization parts are acceptable.

Contact Yixing Plastic for more information about getting a quote, placing an order, or finding solutions to your application